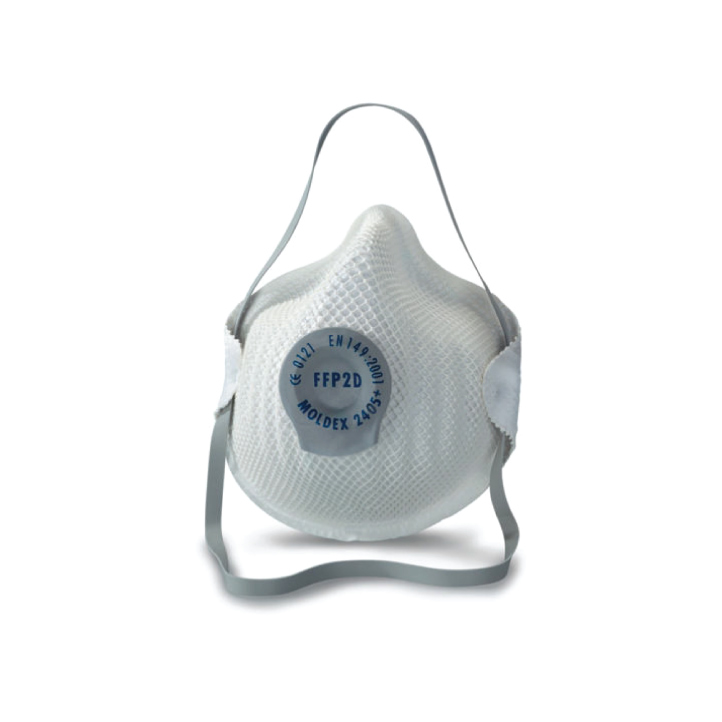

The Moldex Classic Series Valved Respirator is a perfect example of a FFP2 mask that can help adjust to different face shapes and with its added DuraMesh shape it is very durable in many hazardous situations.

this FFP2 mask performs well in many areas in industries that require breathing masks, such as being involved in fine toxic dusts, fumes and water-based mists/aerosols.

his Moldex FFP2 mask will help the wearer be protected from any hazardous chemicals or dusts while working on the job in hand.

To further reduce moisture and heat, this FFP2 mask can be equipped with a Ventex valve.These breathing masks come in a box of 20.

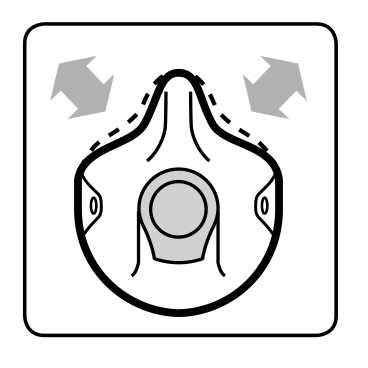

ActivForm®

Automatically fits to the face.

No manual adjustments by the user are necessary

DuraMesh®

Masks have a strong and durable structure.

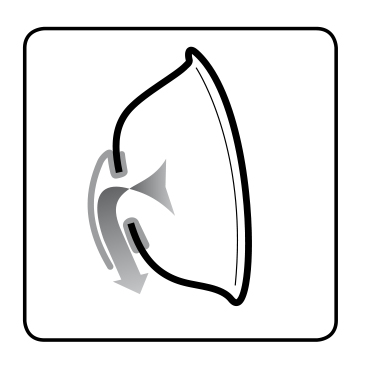

Ventex®-valve

Starts to open even at low exhalation pressure and significantly reduces moisture and heat inside the mask.

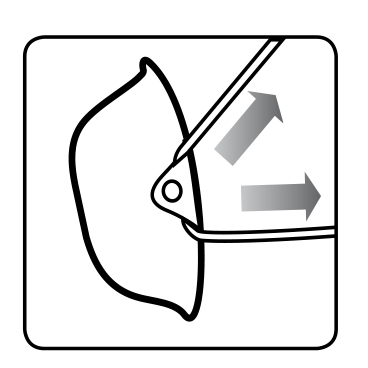

Adjustable Strap

Makes it easier to take the mask on and off and to adjust to different head/neck dimensions.

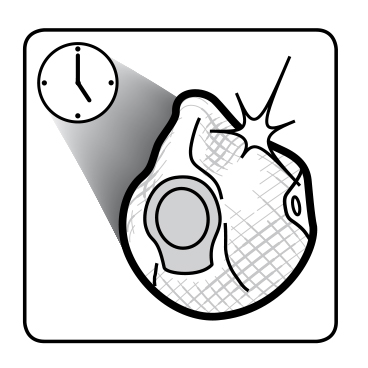

Dolomite clogging test

Masks have passed the Dolomite clogging test, giving the

user better breathing resistance for longer

100% PVC-FREE

All Moldex products and packaging are completely free from PVC.

The Moldex Classic Series FFP-masks meet the requirements of

EN 149:2001+A1:2009 and are CE-marked in accordance with the requirements of European

Directive 89/686/EEC. The IFA (0121) Germany is responsible for both type examination (Article 10) and monitoring of production (Article 11B).

The products are manufactured in an ISO 9001 certified plant.

Filter Layer, Inner Shell, DuraMesh®: Polypropylene,

Ethylene-vinyl acetate (EVA)

Head Strap, VentexValve®: Natural Rubber

T E S T I N G A C C O R D I N G T O N 149:2001+A1:2009

Total inward leakage

Ten test subjects perform a variety of exercises. During the exercises the

amount of test aerosol that penetrates the filter, face seal and valve are sampled. The total inward leakage of 8 out of 10 test subjects shall not exceed the following levels:

Max. total inward leakage 8%

Max. Filter penetration

The filter penetration after loading the filter with 120 mg paraffin oil according

to DIN EN149:2001+ A1:2009 shall not exceed the following levels:

Max. Filter penetration 6%

Flammability

4 respirators are passed through a 800°C (+/- 50°C) flame with a speed of

6 cm/s. After passing through the flame the respirator has to self-extinguish.

Breathing Resistance

The breathing resistance produced by the filter of the respirator is tested at an

airflow of 30 l/min and 95 l/min.

Max. breathing resistance according to EN 149

30 l / min – 0,7 mbar

95 l / min – 2,4 mbar

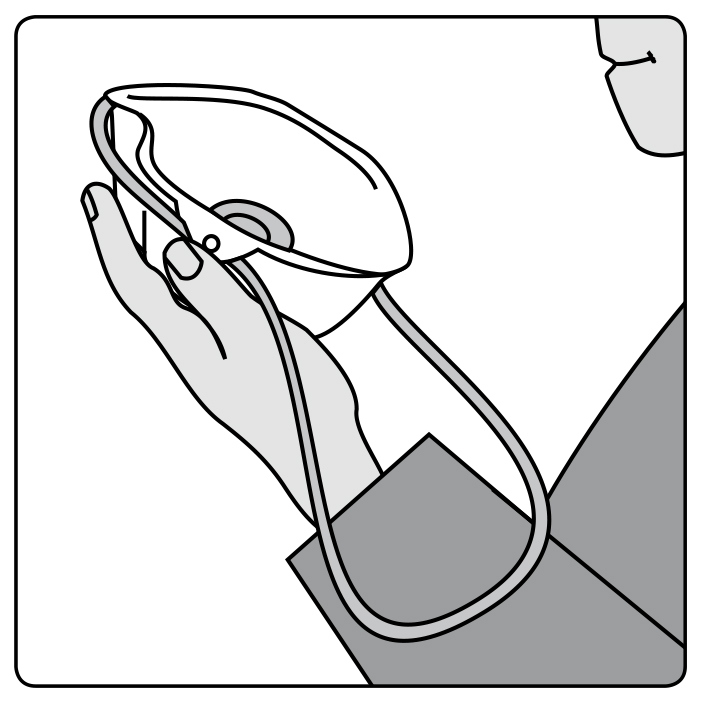

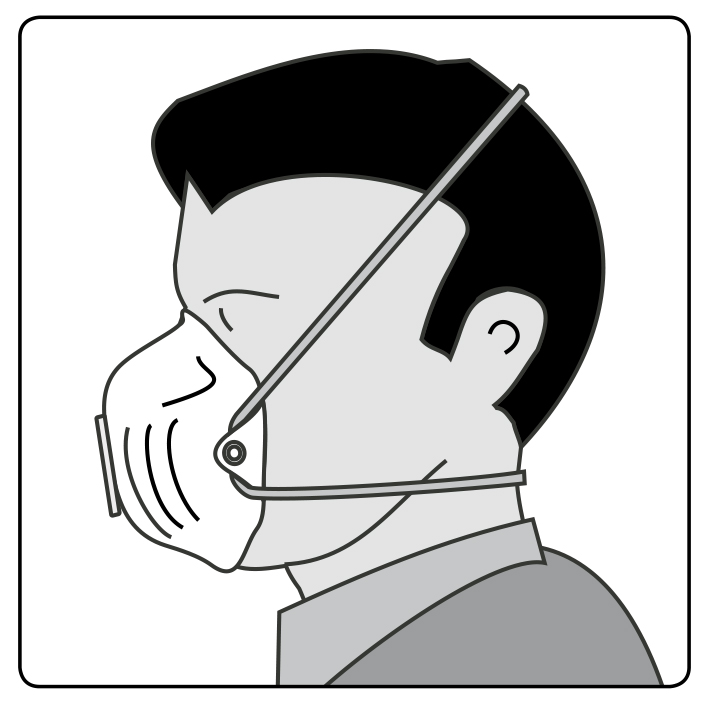

1. Pull strap to form a large loop.

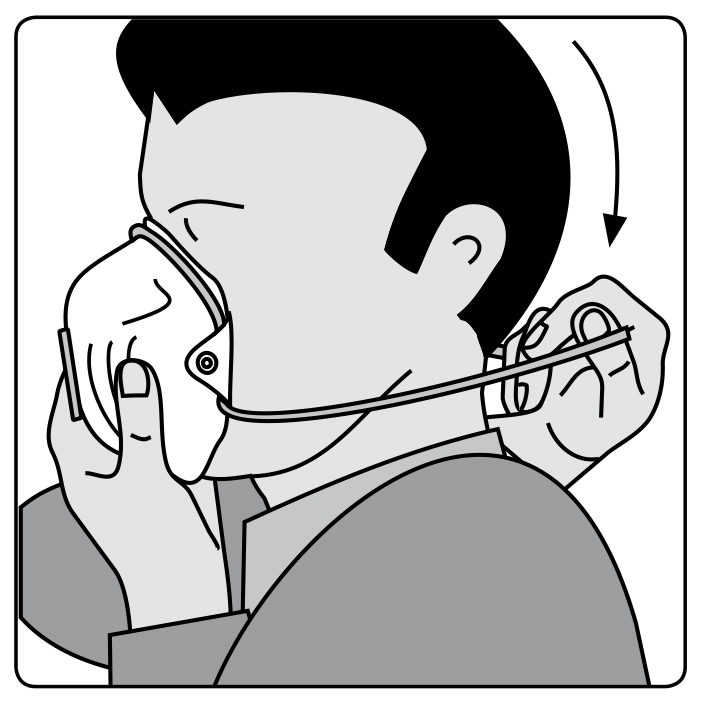

2. Place respirator on chin and

pull loop over head tight to

the neck

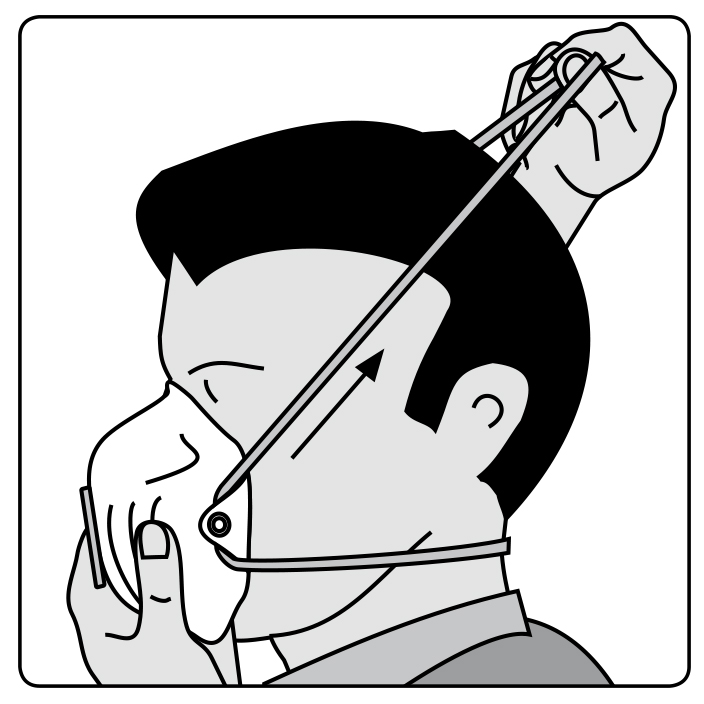

3. Pull upper strap tight and

then place on back of head.

4. Ensure respirator fits secure

and comfortable.